What Type of Production Process Best Describes Most Cpg Manufacturing

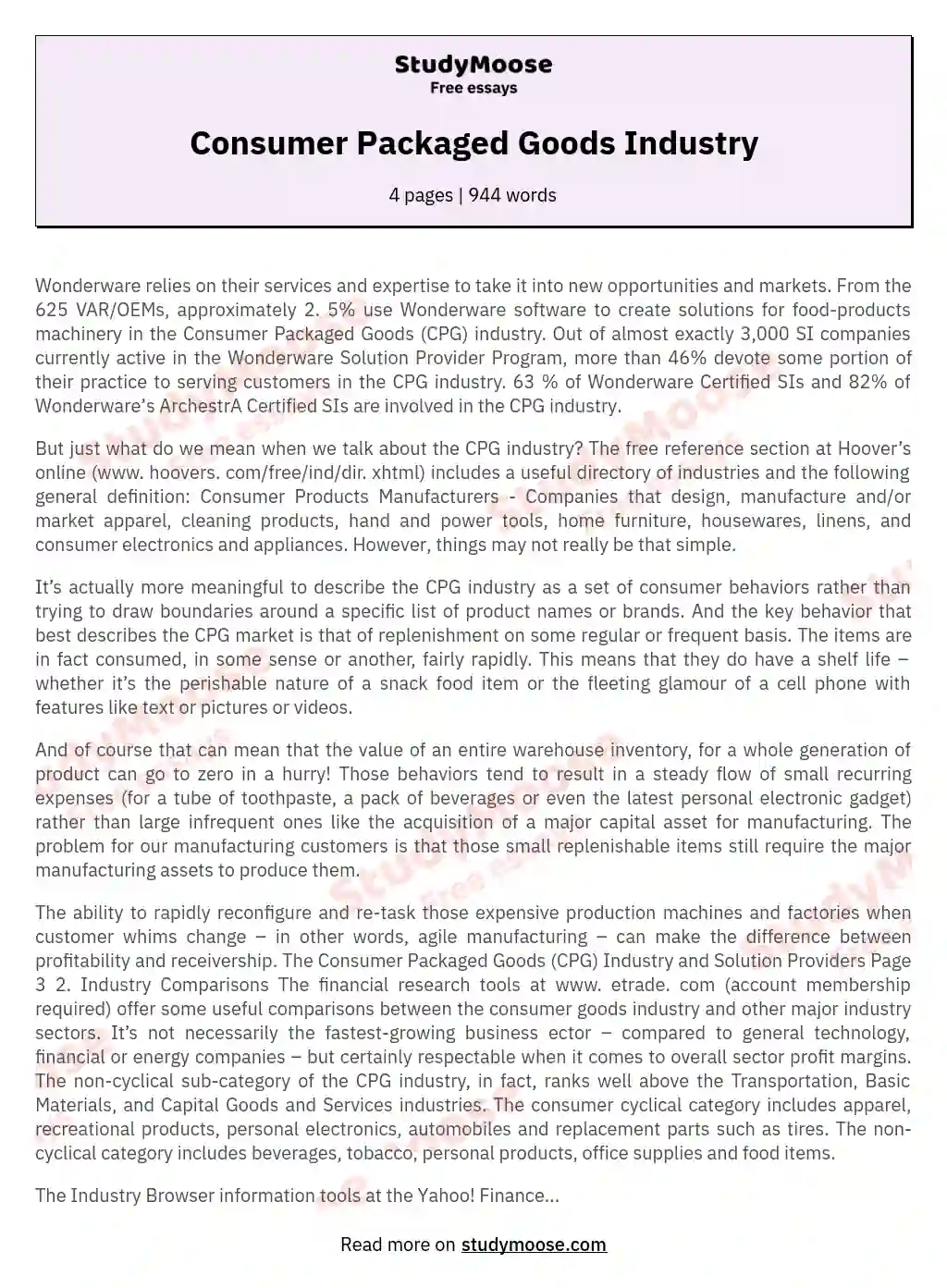

As everyone in the fast-moving CPG industry knows modern business requires an astute understanding of exactly where your market is and how it is moving often resulting in new. Across the Consumer Packaged Goods industry manufacturers continue pushing to eliminate idle time control production costs and coordinate operations across plants.

How To Describe Automation By Functionality Arc Advisory

Producibility Engineering and Planning focuses on key processess and key product characteristics as well as.

. Those categories include casting and molding machining joining and shearing and forming. Materials tools and products are standardized. Every operation is unique and the same production plan isnt right for everyone.

Manufacturing process planning and production resource planning. The common types of production process. Project-based production is one-of-a-kind production in which only one unit is manufactured at a time.

Why Use Pre-Employment Testing. In manufacturing it is not just the final products where kitting could prove to be beneficial. A job shop is used to process low volume high customized goods.

94 of manufacturing executives view training programs as one of the most effective ways to close the skills gap. One of the best examples of mass production is the manufacturing process adopted by Ford. View Test Prep - C3_MCQ from BUSS 5357 at University of South Australia.

All businesses follow their own set of operation so its essential to know the differences between various production methods to ensure that you are selecting the most suitable. Manufacturing takes products from idea to completion. Project- or Job-Based Production.

There are several standard manufacturing processes applied across industries and companies can vary which they use or tailor productions to design and business needs. Which describes the manufacturing process types. In order to get the most from project planning you need to decide which method is best for your manufacturing process.

CPG companies are investing resources in ongoing change initiatives at higher levels compared to overall respondents. But as a manufacturer you could also use kitting to bundle up parts and materials before the production process in order to make production more efficient by eliminating the. In fact only 5 percent of CPG executives stated that their companies have decreased the amount of resources spent on change management initiatives in the past 12 months compared to 11 percent of overall respondents.

Process layout is best suited method for mass production units. That said heres a quick intro to the different types of production planning. As we examine the four major types of production processes keep in mind that the most successful organizations are those that have their process and product aligned.

This type of production is often used for. The production process is intermittent and adjusted for each project. They each deploy a.

In production planning the first decision involves which type of production process the way a good or service is createdbest fits with company goals and customer demand. 1 Job Shop Manufacturing Process. Product variety is usually very low which may be one of its kind.

Mass production is also known as flow production or assembly line production. In this article we explore what a. A separate machine or a number of machines of one type are used for one process.

Batch of one product then may switch over These are called batch manufacturing. The manufacturing process is broken into separate operations. Flow production is the manufacture of a product by a series of operations each article going on to a succeeding operation as soon as possible.

In most cases the two biggest expenses in your manufacturing business. Set up the equipment and make a batch of Batch means a. Consumer packaged goods CPG are items used daily by average consumers that require routine replacement or replenishment such as food beverages clothes tobacco makeup and household products.

6 Types of Manufacturing Processes. Which type of layout best describes one that is used to make a small batch of highly customized products. An important consideration is the type of good or service being produced because different goods may require different production processes.

Chapter 3 - Process Types 1. When considering your manufacturing options theres a number of production methods with each offering its own unique set of benefits depending on product type and market size. Of course manufacturers can distribute their products in kits as well.

The _____ is one of the best mass production processes for manufacturing products that are identical. Mass Production Mass production is the continuous production of items. Types of Production Processes Batch Manufacturing Batch Manufacturing Many manufacturing operations fall between The batch manufacturing company makes a job shops and repetitive manufacturing.

3 Mass Production or Flow production. Types of Production Planning. Identifying any new processes or materials as soon as possible and planning development concurrently with the product design.

The semi-finished product keeps on moving from one operation point to the succeeding operation point throughout the production process. The Four Basic Process Types. It is important to grow the top line of your business on an annual basis but you also need to make sure the bottom line is healthy which can help fund that growth.

This type of manufacturing is highly flexible and able to produce a wide variety of goods. 9 Best Practices for your Daily Scrum Meeting Blog Just in Time Process Excellence Production Production Systems. This is particularly important if you are a manufacturing company and need to be efficient in your production process.

It is one of the most common types of products used in the automobile industry and is also used in industries where continuous production. Most of the production process is differentiated. There are many types of manufacturing but they fall into four major categories.

Manufacturing is the making of goods from televisions and automobiles to guitars and clothing. While you cant magically create a pool of skilled applicants one of the best ways to select the right employees for manufacturing roles is by identifying potential.

Consumer Packaged Goods Industry Free Essay Example

The Product Development Process Listening Learning Launching B2b International Usa

:max_bytes(150000):strip_icc()/dotdash_Final_Analyzing_Starbucks_Value_Chain_Oct_2020-01-d263a993151e430f95fccd3898dfbd6a.jpg)

Analyzing Starbucks Value Chain

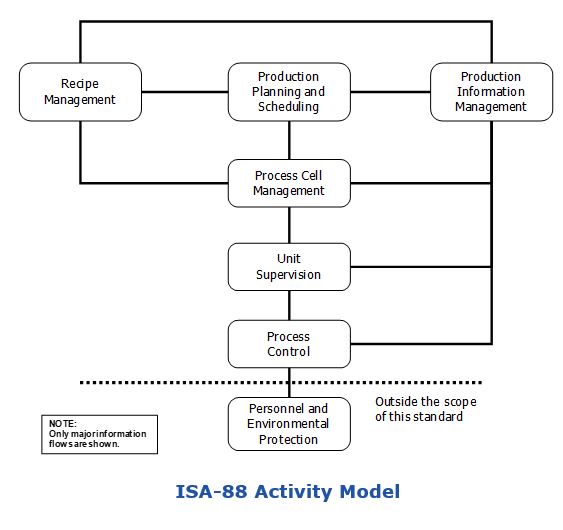

Importance Of Industry Standards With Automation Arc Advisory

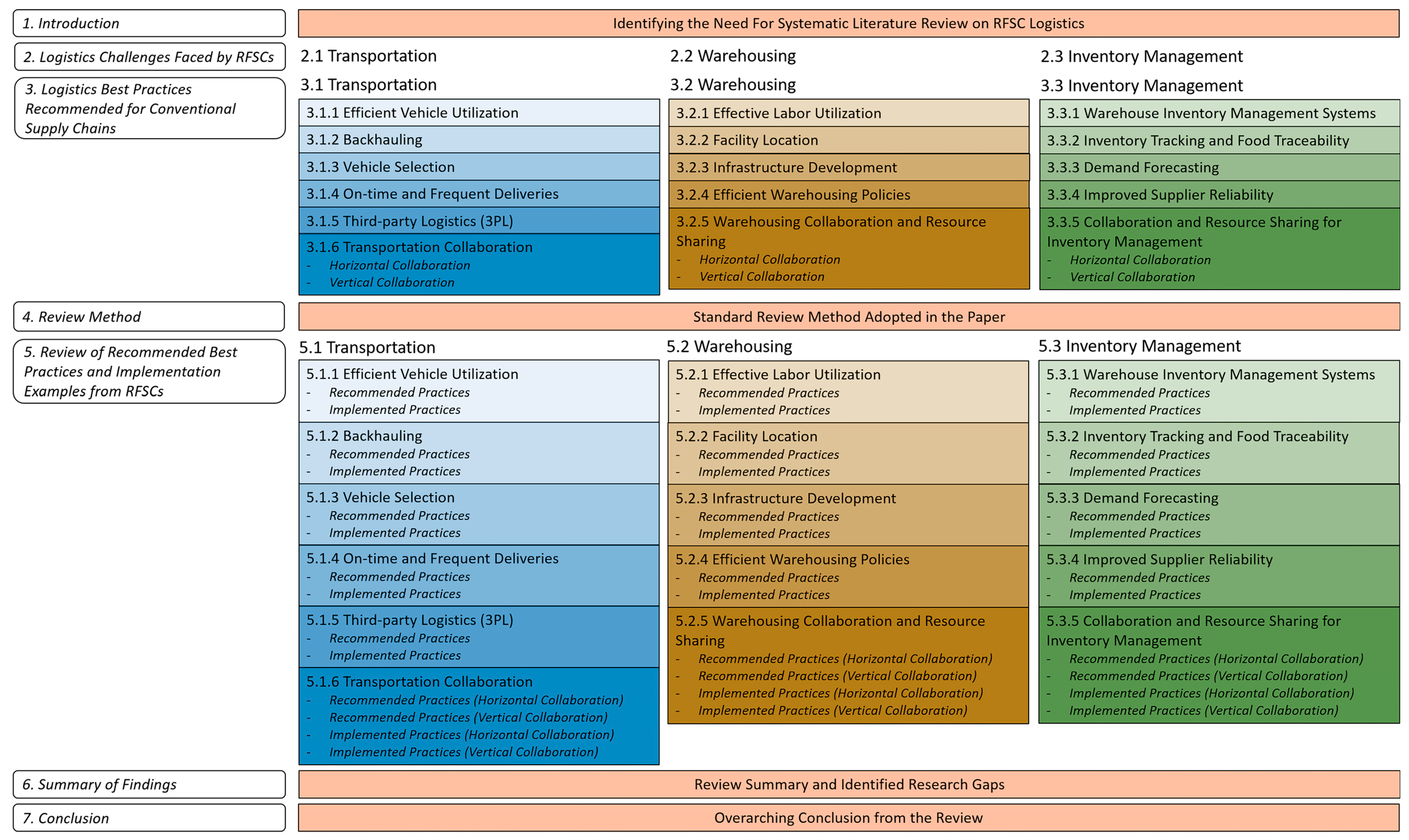

Sustainability Free Full Text Logistics Best Practices For Regional Food Systems A Review Html

How To Describe Automation By Functionality Arc Advisory

How To Describe Automation By Functionality Arc Advisory

0 Response to "What Type of Production Process Best Describes Most Cpg Manufacturing"

Post a Comment